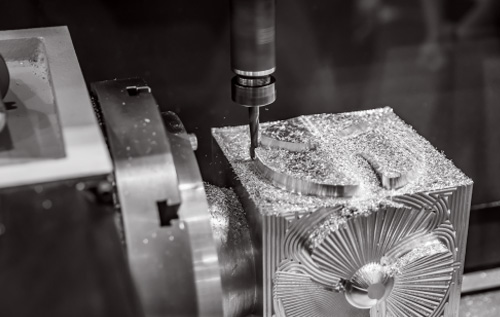

Our skilled team consistently delivers innovation and quality in precision parts manufacturing.

Optimize Layout: The layout of the warehouse should be designed to minimize the time taken to move products from one location to another. A well-organized layout can reduce the travel time of the workers and the forklifts, which can significantly increase productivity. To optimize the layout, it’s essential to consider the products’ flow, storage requirements, and the equipment used.

Automate Processes: Automation of certain processes can improve warehouse efficiency by reducing human errors and minimizing the time taken to complete a task. For instance, using automated conveyor belts, robotic palletizers, and automated storage and retrieval systems (ASRS) can enhance the speed and accuracy of product movement. Automation also enables the workers to focus on more critical tasks that require human intervention.

Implement Inventory Management: Inventory management is essential for minimizing the inventory carrying costs, improving customer service levels, and ensuring that products are available when required. By implementing an efficient inventory management system, companies can reduce stockouts, overstocks, and obsolescence. This ensures that the right products are available in the right quantities and at the right time, which helps in meeting customer demand.

Training and Development: Training and development of the warehouse staff can significantly impact the efficiency of the warehouse. Providing regular training on safety measures, operating equipment, and warehouse processes can help reduce accidents and errors. A well-trained staff can work more efficiently, leading to a more productive and safer warehouse environment.

Implement Lean Principles: Lean principles focus on eliminating waste, reducing lead times, and improving quality. By implementing lean principles in the warehouse, companies can reduce unnecessary steps, inventory, and space requirements. This, in turn, leads to more efficient and effective operations, resulting in cost savings and improved customer satisfaction.

Use Data Analytics: Data analytics tools can provide valuable insights into the warehouse operations, allowing companies to identify areas for improvement. By analyzing data related to inventory levels, order accuracy, and delivery times, companies can make informed decisions to optimize the warehouse’s performance continually.