Mastering Precision Machining: A Confluence of Skill, Precision, and Technology

Precision machining is an essential process in modern manufacturing, ensuring parts are produced to exact specifications with an incredible degree of accuracy. It is the backbone of many industries, from automotive to aerospace, healthcare to high-tech. Mastering this process requires a unique blend of technical skill, attention to detail, and sophisticated technology. In this post, we delve into what it takes to excel in precision machining.

Craftsmanship and Skill

At the heart of precision machining is the craftsman’s skill. Whether programming a computer numerical control (CNC) machine or carefully monitoring a production run, machinists must have a deep understanding of materials, tools, and processes. They are not just machine operators but artisans, combining deep technical knowledge with a keen eye for detail.

Machinists need to understand material behavior under different machining conditions. The characteristics of aluminum differ vastly from stainless steel or brass. Likewise, they must have comprehensive knowledge of cutting tools and machining techniques, ensuring each part is manufactured to the highest standards.

The Precision Imperative

Attention to detail is paramount in precision machining. The manufacturing of parts to incredibly tight tolerances — often to within a few micrometers — requires meticulous planning, execution, and quality control.

Achieving such precision is a rigorous process. It starts with precise CAD drawings, followed by exacting programming of the CNC machines. It includes careful selection of cutting tools, speeds, and feeds, then extends to the manufacturing process itself, where constant monitoring ensures compliance with specifications. Lastly, thorough quality control inspections verify the precision of the final product.

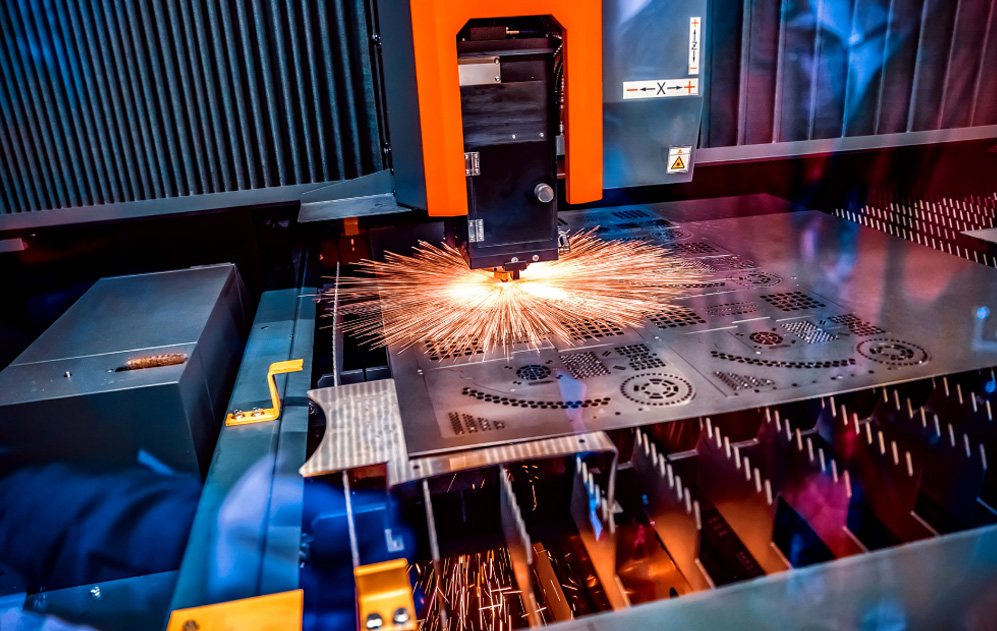

Harnessing Technology

The advent of advanced technologies has revolutionized precision machining. CNC machines, able to carry out complex sequences of operations automatically, have become an industry standard. These machines deliver unprecedented levels of precision and repeatability, making them an invaluable tool in a machinist’s arsenal.

Further advancements include high-speed machining techniques and the use of AI in predictive maintenance and quality control. Sophisticated software can now simulate machining processes, optimizing them before a single piece of material is cut.

The Journey to Mastery

Mastering precision machining is a journey that begins with a deep understanding of materials and tools, develops with a relentless focus on precision, and is continually honed through the adoption of advanced technologies. It’s a journey that demands commitment, patience, and passion. However, the rewards — in the form of superior quality parts that power our world — are well worth the effort.

At Dee’s Machine, we’ve embarked on this journey over six decades ago and remain committed to delivering excellence. We understand that precision machining is more than a process; it’s a craft that requires dedication and a relentless pursuit of perfection.